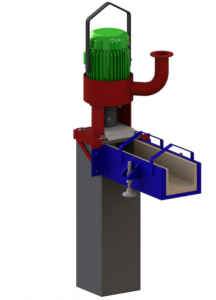

Raptor Quick Immersion Transfer Pump

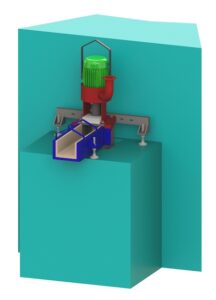

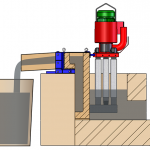

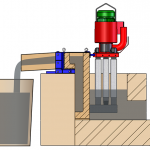

MMEI’s new Raptor transfer pump is the perfect solution to pump out your furnace or fill crucibles, ladles, molds or ingots. Driven by a reliable, high efficiency electric motor, this pump has mobile controls and an integrated cooling blower to make sure the motor is always cooled. Used for aluminum and zinc, the Raptor is lightweight, portable and can be moved around easily to plug into any receptacle. The pump body is made from graphite, which allows quick immersion for fast use with flow rates up to 800 lbs. (360 Kg) per minute. Available in four lengths, this is the transfer pump you need to get the job done.

RESOURCES

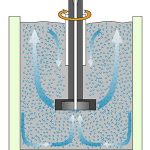

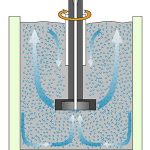

The rugged body is made from graphite and has unique “vortex busting” pathway to reduce dross formation

Available in multiple lengths to meet your needs: 15″ (381mm), 21″ (533mm), 27″ (686mm), 33″ (838mm)

Perfect for transferring directly to another furnace or into ladles

FEATURES

- For use with molten metal such as aluminum and zinc

- Quick immersion pump! The pump body is made from graphite which allows quick immersion.

- Use to pump out your furnace and to fill crucibles, ladles, molds or ingots.

- Flow rates up to 800 lbs. (360 Kgs.)/min

- Small footprint allows access through small openings – base is only 10″ x 10″ (254 x 254 mm)

- Rugged pump construction, built for the harsh molten metal environment

- Driven by a reliable, energy efficient electric motor, which allows for variable speed operation for varying metal flow.

- Cooling blower attached to pump ensures electric motor is always cooled.

- Heavy duty shaft designed to maximize service life while reducing vortexing.

BENEFITS

- Light weight and portable for easy movement throughout a plant

- Eliminate the costly expense of riser tubes and transfer piping

- Engineered to provide long service life

- Designed for easy assembly and repair

- Refractory lined launder sections available in lengths up to 48″ for use with the pump.

- Special rotor design pushes metal upwards, reducing vortexing around the shaft while minimizing turbulence.

- Wide pump outlet (launder connection) provides quiescent metal flow and reduces dross formation.

- Rugged body is made from graphite and has unique “vortex busting” pathway to reduce dross formation.

PROCESS INFO

OTHER PROCESSES

Molten Metal Transfer

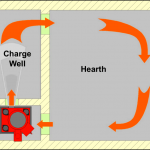

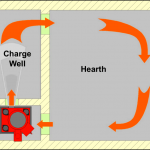

Furnace Circulation

Degassing Process

Gas Injection

Molten Metal Transfer

Furnace Circulation

Degassing Process

Gas Injection